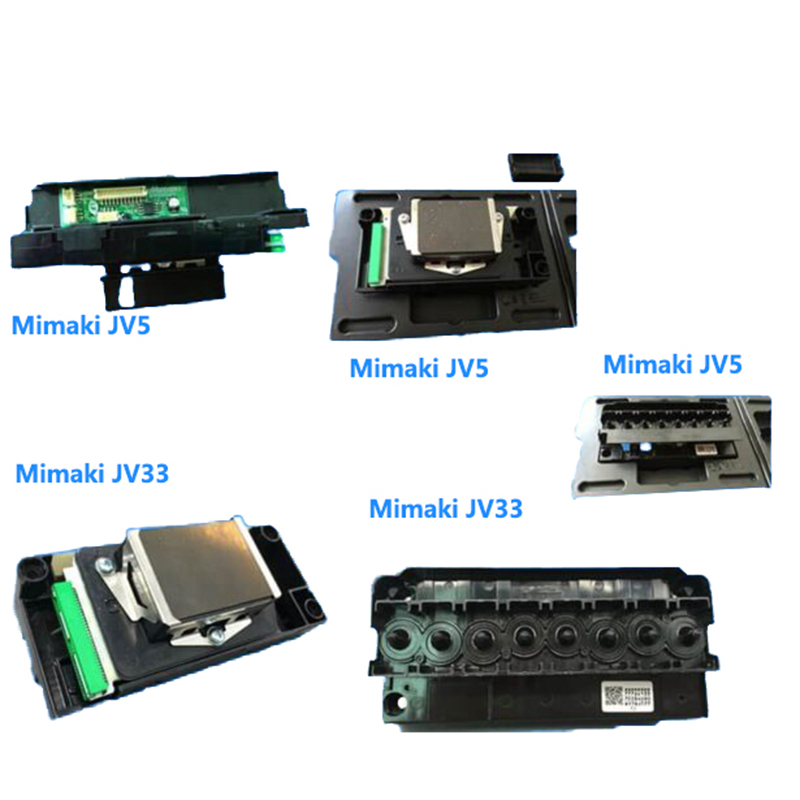

Mimaki DX5 printhead, original heads, good price

Armyjet has a keen eye for the market. It knows perfectly what the market really needs.

Armyjet develops a new printer based on the market. And for each new printer, we will test it about 6-12 months before it enters the market.

During our process of developing a new printer, we will do a lot of market research, test all the important parts at least three times, print samples for at least 8 hours one day, etc.

Note: For more information and fast response, please scan the QR code below to add our Wechat.

Mimaki JV33 head specification

| TECHNOLOGY | Micro-piezo |

| ACTIVE NOZZLES | 1440 (8 lines x 180 nozzles) |

| MAX. RESOLUTION | 1440 dpi |

| INK TYPE | Eco-solvent, UV INK |

| DROP VOLUME | 3.5PL |

| FIRING FREQUENCY | 10 KHZ |

| SUITABLE PRINTER | MIMAKI JV33 |

How Does Armyjet Develop a New Printer

Mimaki JV5 head Specification

| TECHNOLOGY | Micro-piezo |

| ACTIVE NOZZLES | 1440 (8 lines x 180 nozzles) |

| MAX. RESOLUTION | 1440 dpi |

| INK TYPE | Eco-solvent, UV INK |

| DROP VOLUME | 3.5PL |

| FIRING FREQUENCY | 10 KHZ |

| SUITABLE PRINTER | MIMAKI JV5 |

How Does Armyjet Get the Best printing quality and Most Stable Performance

There’s no magic: just focus more on details and test more. Armyjet encourages its customers to offer suggestions to improve printers.

Once Armyjet uses the suggestion from customers, Armyjet will give a prize to this customer, a prize will last at least one year.

How about Armyjet Technical Team

Armyjet cherishes each excellent technician. 50% of technicians have worked in Armyjet for more than 10 years.

Armyjet encourages its technicians to solve problems as soon as possible. And technicians can obtain a potent for its good solutions.